Analysis of Top Ten Engines in the World in 2010 with New Technology in Power

Ward’s Auto World, the authoritative American automobile magazine, selects the top ten engines in the world every year. At the end of 2009, the magazine selected the latest top ten engines in the world in 2010. These include two hybrid engines, two diesel engines, one supercharged engine, three turbocharged gasoline engines and two naturally aspirated engines. To enter Ward’s Top Ten Engine Candidate List, the participating vehicles must be less than $54,000, and the engines must be in production and can be purchased in the first quarter of 2010.

| Ward’s Top Ten Engines in the World in 2010 | |

| engine | Application vehicle type |

| 2.0L TFSI turbocharged direct injection | Audi A4, A5 |

| 3.0L TFSI V6 supercharged direct injection | Audi S4, A6 |

| 3.0L inline 6-cylinder turbocharged diesel oil | Bmw 335d, 535d, X5 xDrive35d, X6 xDrive35d |

| Ford 2.5L hybrid | Ford Fusion Hybrid |

| 3.5L EcoBoost V6 turbocharging | Ford Taurus SHO |

| Universal 2.4L Ecotec | Buick New Regal and New LaCrosse |

| Hyundai 4.6L V8 | Modern Lawns (American Edition), Jacobs |

| 2.5L horizontally opposed 4-cylinder turbocharging | Subaru legacy 2.5GT |

| 1.8L hybrid power | Toyota Prius |

| 2.0L TDI turbocharged diesel oil | American Volkswagen Jetta, Golf |

Six editors of Ward’s Auto World tested 34 new cars from 13 brands in October and November last year, which were close to daily driving conditions. They comprehensively evaluated the horsepower, torque, technical content and working characteristics of each engine in actual use, and finally selected ten engines with the best comprehensive performance. There are five brand-new engines in this year’s winners’ list, which reflects the development trend of engines to small displacement. Now more car owners have listed fuel economy as an important consideration. Of course, the performance of the engine can not be ignored.

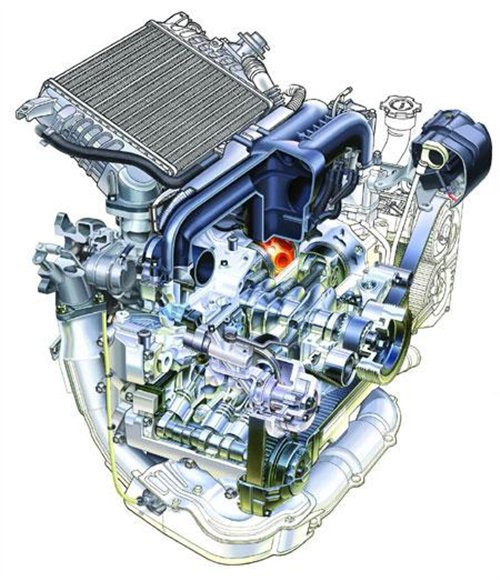

Audi 2.0L TFSI Turbocharged Direct Injection Engine

Technical features: Strong combination of in-cylinder direct injection and turbocharging.

Application models: Audi A4, A5

Audi 2.0TFSI engine is the EA888 2.0TFSI engine adopted by domestic Audi A4L. FSI means Stratified Injection of Fuel, and T means Turbo. This technology combines the advantages of gasoline engine and diesel engine, which not only has strong power, wide torque range and active speed increase, but also saves 15% fuel compared with the non-direct injection model originally used by Volkswagen, which is the biggest advantage of direct injection in cylinder plus turbocharging. In order to meet the more demanding conditions put forward by the turbocharger, the cylinder block is still made of cast iron, which can withstand higher combustion temperature in the cylinder. Audi’s advanced technology is also integrated in many other details.

1. Variable intake manifold and intake camshaft continuous adjustable device

The VVT of Volkswagen’s previous generation EA113 frame engine still depends on the transmission chain tensioner between two camshafts, which is a thing of the past. Such VVT adjustment range is very limited and it is not easy to control. The new EA888 frame adopts a much more accurate vane-type control device, which is a variable valve lift technology developed by Audi. At present, most Audi engines are equipped with this technology, and the driving gear end of the intake camshaft is equipped with a vane-type camshaft phase adjustment device, which can ensure that the intake valve timing can be continuously adjusted.

2. Timing chain replaces timing belt.

The new EA888 frame engine replaces the original timing belt with a more durable timing chain. The service life of the timing chain is almost as long as the service life of the car. The advantages of using the timing chain are not only reducing the car maintenance cost of the owner, but also shortening the length of the engine and reducing the size and weight of the front part of the car with the longitudinal engine.

3. More reasonable balance shaft position

The new engine balance shaft is designed at the lower end of the cylinder block, which is driven by the crankshaft and chain. The centrifugal force generated by it is just opposite to the centrifugal force generated by the crankshaft, so that most of the vibration can be offset, and the vibration you feel from the steering wheel will become more subtle. Compared with the old engine, it is closer to the balance shaft position of the oil pan, and the new balance shaft position is undoubtedly more reasonable.

4. Four valves and new valve drive structure

The roller rocker arm is used in the valve driving structure, which reduces the friction between the rocker arm and the camshaft surface, eliminates the valve clearance with the cooperation of the valve hydraulic tappet, and makes the noise of the valve and rocker camshaft less when operating.

5. Water-cooled turbocharger

Turbocharger is the power source of Turbo engine, and the working environment of turbocharger is very bad, among which high temperature is the sworn enemy of turbocharger. A 1.8T engine based on EA113 architecture (such as the one above Bora 1.8T) needs to idle for a few minutes after long-term operation, so that the engine oil can fully cool the turbocharger and ensure the service life of the turbine. The water cooling system can better solve the cooling problem of the turbocharger and prolong the normal service life of the turbocharger. However, this method does not solve the lubrication problem of the turbocharger rotor after flameout. Therefore, after intense driving, it is necessary to keep the engine running for a period of time after parking to ensure that the engine oil can fully lubricate the rotor.

Audi 2.0TFSI engine can produce the maximum power of 211 HP (155kw) in the range of 4300-6000 rpm, and the maximum torque can reach 350Nm from 1500 rpm to 4200 rpm, which can make A4L weighing more than 1.6 tons break 100 in 7.3 seconds. However, this engine is not perfect in China. Due to the quality problems of domestic oil products, its very important stratified combustion technology has been cancelled, and the phenomenon of burning engine oil has been bothering most Audi owners. There is no perfect solution to the phenomenon of burning engine oil until now, but it doesn’t seem to have much influence on those friends who want to buy A4L. The car is full, so just drink more engine oil.

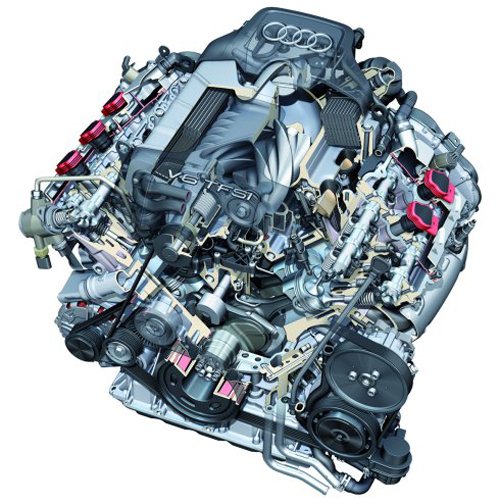

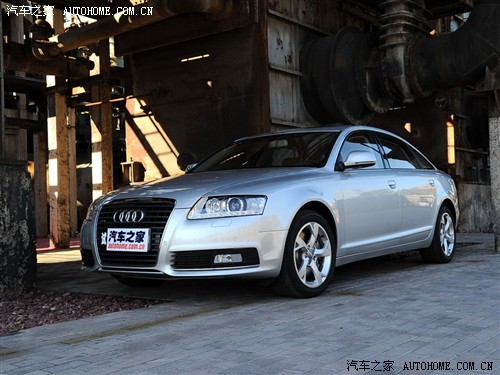

3.0L TFSI V6 supercharged direct injection engine

Technical features: All-aluminum cylinder, combination of mechanical pressurization and direct injection in rigid body.

Application models: Audi A6L, S4

Literally, we can see the difference between turbocharging and turbocharging. Turbocharging is driven by exhaust gas, while turbocharging is driven by shaft. Audi’s 3.0L supercharged engine has attracted much attention since it was officially launched in 2008, for the simple reason that it is the first supercharged engine of Audi in recent 40 years. This supercharged engine adopts Audi’s latest technology in many aspects.

1. Short gas path brings ultra-fast dynamic response.

The gas path of the supercharger is very short, which means that the torque increases very quickly and the response speed greatly exceeds that of the naturally aspirated engine with the same displacement. The 3.0 TFSI engine is very sensitive to the throttle, it can easily soar to 6500 rpm, and the rated output power can reach 290 horsepower below 5000 rpm.

2. Lightweight engine

The crankcase with a displacement of 3 liters cast by aluminum-silicon alloy weighs only 33 kilograms. The engine, including supercharger, weighs only 189 kilograms.

3. The driving force required by the supercharger is very low.

We all know that the supercharger is driven by shaft transmission. Different from the traditional concept, the use of FSI technology allows the supercharger to be arranged behind the throttle valve. In this way, the air density passing through the supercharger is very low under low load or circulation, and the rotor is almost free to rotate, so the required driving force is very small. In this way, when the accelerator is deeply stepped on, the supercharger will not start from a static state, ensuring a rapid response time.

4. Reinforced crankcase

Audi also improved the stress level of crankcase on the 3.0 TFSI engine, and the friction resistance between related components was minimized. The phase adjustment range of the two intake camshafts reaches 42 degrees crank angle, thus forming an intake vortex which is more conducive to oil-gas mixing in the intake port. Combined with the in-cylinder direct injection system, fuel injection can be carried out up to three times in each compression stroke, thus further improving the performance of this engine.

Compared with the turbocharger, the supercharged engine has some inherent advantages, such as its faster working response, which is particularly important in the initial stage of the vehicle. According to the official data, this 3.0TFSI engine can have a torque of 420 Nm from 2500 rpm, and this torque can last until 4850 rpm. The 1.9-ton A6L with this 3.0TFSI supercharged engine has an acceleration time of only 6.6 seconds per 100 kilometers (official data, conservative).

BMW 3.0L inline 6-cylinder twin turbocharged diesel engine

Technical features: higher torque output, more environmentally friendly emissions.

Application models: BMW 335d, 535d, X5 xDrive35d, X6 xDrive35d (not introduced in China).

The 3.0L inline 6-cylinder twin-turbo diesel engine of BMW 335D is the top version of M57TU2D30 in BMW M57 series engines. This engine adopts two turbines, large and small, which can intervene at different engine speeds, and at the same time, it gives up the adjustable turbine blades in the original turbocharger, which improves the response speed of the turbocharger.

1. Variable twin turbocharging system

The new diesel engine adopts a variable double turbocharging system, and a cleverly designed system can start two turbochargers successively, which not only improves the efficiency, but also strengthens the reaction ability of the supercharger, and at the same time gives up the adjustable turbine blades in the original supercharger. These two superchargers work in strict accordance with the classification theory. When the engine speed is below 1500rpm, the smaller supercharger responds quickly and takes the initiative to supply gas. When the rotating speed is in the range of 1500rpm-2500rpm, both superchargers start to work. At this time, the large supercharger plays the role of pre-boosting; When the rotating speed exceeds 2500rpm, the supercharger starts to work at full load, providing a pressure of O.18MPa (the intake pressure is O.15MPa). The supercharging system is equipped with two valves and several pipelines to control the airflow and air quantity entering the supercharger, and the waste gas and fresh air are distributed to the two superchargers according to the instructions. This dual-supercharging system takes up a lot of space, so it can’t be applied to the smaller V6 engine.

2. The application of aluminum and magnesium makes the engine lighter.

The highlight of the improved gasoline engine lies in the composition of the engine cylinder block material. BMW successfully combined magnesium (Mg) and aluminum (A1) in the casting process, making good use of the characteristics of these two metals, and using aluminum alloys in places with high working intensity, such as crankshaft support, cylinder block inner wall and cylinder block, but the outer wall of the cylinder block and oil pan are mostly made of magnesium alloys. This not only ensures the robustness of the engine, but also reduces the quality of the whole machine. The mass of crankcase and cylinder head of straight 6 engine made of magnesium alloy is also greatly reduced. Compared with aluminum alloy box, the mass of new material box is reduced by 24kg.

Diesel engines all have strong low-torque performance, and they start to exert their power at 1500 rpm. With the help of turbocharging, BMW 3.0 dual-supercharged diesel engine also has excellent intake and exhaust performance in the high-speed range, and will have a very strong power output when the speed continues above 5000 rpm. The maximum power of this engine reaches 265 HP (194kw)/4200rpm, which can provide the highest torque output of 576Nm, and the thrust is amazing at low speed. At the same time, in terms of emissions, it is also more environmentally friendly than gasoline engines of the same level. Overseas, diesel engines are very popular, but in China, due to various reasons, diesel vehicles are not taken seriously, so such a diesel engine with excellent performance cannot enter the China market.

Ford 2.5L Hybrid Hybrid Engine

Technical features: hybrid power of oil and electricity

Application model: Ford Fusion Hybrid (not introduced in China)

Ford Fusion’s 2.5L Hybrid engine is also available only in the United States. This hybrid system consists of a gasoline engine with a displacement of 2.5L, an AC motor and a set of Ni-MH batteries. The fuel economy is excellent. Under normal circumstances, the high-speed fuel consumption is 5.7L and the urban fuel consumption is 6.5L.. A 2.5L gasoline engine can generate a maximum power of 142KW(191HP) and a torque of 184 N m (136 LBFT).

1. New battery system

The hybrid system applied to Ford Fusion is already the second generation hybrid system of Ford. The new hybrid power system uses 208 batteries, which is much less than the previous generation of 250 batteries, but the battery power is increased by 20%, largely because the battery supplier Sanyo Electric Company improved the current collector, reduced the thermal resistance in the circuit, and improved the chemical properties of the hydrogenated alloy as the negative electrode of the battery. This design reduces the weight by 29kg while ensuring sufficient power supply.

2. More efficient motors

Compared with the first generation hybrid system, the VVC developed by Ford can improve the efficiency of traction motor by 130% and generator by 160%. When the battery voltage drops to a predetermined level in a specific operating environment, the VVC device installed with the high-voltage electronic equipment of the transmission can increase its voltage. The characteristic of VVC is that it can provide extra voltage when needed, such as acceleration, emergency braking and when the system needs extra electric power.

As a hybrid power system, fuel economy is the most important. Ford 2.5L hybrid hybrid power system can be driven by pure electric power at low speed. Under normal driving conditions, gasoline will intervene to provide power for the vehicle. The fuel consumption per 100 kilometers in urban road conditions is 6.5L, and it can be reduced to 5.7L at high speed, which is quite satisfactory for a car with a displacement of 2.5L..

Ford 3.5L EcoBoost V6 turbocharged engine.

Technical features: direct fuel injection, turbocharging and variable valve timing.

Application model: Ford Taurus SHO (not introduced in China)

The concept of Ecoboost was first introduced around April 2008. Its main technical core is turbocharging, in-cylinder direct injection and variable valve timing technology, aiming at improving engine power performance and fuel economy. Simply put, it means "achieving higher power output with less fuel consumption". The 3.5L V6 engine is the first engine in the Ecoboost family, equipped with twin turbochargers, with a maximum power of 261kW and a maximum torque of 474Nm, and its power output has surpassed that of the traditional 4.6L V8 naturally aspirated engine.

1. Special piston top surface

For in-cylinder direct injection technology, the advantage is that the fuel can be directly injected into the cylinder, which can calculate and control the fuel injection quantity more accurately. Compared with out-of-cylinder injection, the fuel loss is reduced, and the purpose of improving efficiency and reducing fuel consumption is achieved. The top surface of the piston of Ecoboost engine has a special curved surface, and the air sucked into the cylinder by negative pressure can form a vortex, which can stir and spray the oil droplets more evenly and make the fuel burn more fully. The fuel injection quantity and time of the engine can reach 300 times per second, and the fuel injection quantity is accurately controlled, so the engine can realize "lean combustion" and "fully burn up every drop of oil" even at low speed, ensure good dynamic response at low speed, and make up for the shortcoming of delayed response of turbocharged engine on the other hand.

2. The legendary "No.9 Cam"

Because the pressure in the cylinder is extremely high, the direct injection in the cylinder needs to apply high pressure to the fuel to inject smoothly, and the pressure of the traditional gasoline pump is far from enough. A "No.9 cam" is designed at the end of the camshaft. This cam is different from the traditional two-head cam shape. It uses a three-head cam to pressurize the fuel, which can inject the fuel into the cylinder at a pressure as high as 200bar. This pressurization method is the same as that used by the new Regal 2.0T DI.

3. Dual variable timing valves for intake and exhaust.

"Variable timing valve technology" is a very popular word nowadays. At high engine speed, in order to suck in more air and make the fuel burn fully, the variable timing valve system can extend the valve overlap time (the time when the intake and exhaust valves open at the same time), improve the intake air volume and better exhaust the exhaust gas in the cylinder. However, at present, many engines with variable timing valve mechanisms only have variable intake valve timing, and few engines use variable intake and exhaust valve technology (dual VVT-i and DVVT engines are all variable intake and exhaust timing). Ecoboost engine uses dual variable timing valve technology of intake and exhaust. Compared with the engine with variable timing of intake valve only, the phase adjustment of exhaust valve can ensure that more exhaust gas can be discharged to drive the turbine at low engine speed, and reduce turbine hysteresis. At the same time, it has a wider adjustment range and higher flexibility for intake and exhaust efficiency, so its efficiency is higher than that of ordinary engines.

Ford Taurus SHO equipped with this engine has an excellent torque curve. From 1500rpm to 5250rpm, the engine will maintain the maximum torque output of 455Nm. As a turbocharged model, this performance is really rare. In terms of fuel consumption, the city and high-speed fuel consumption of this car are 12 liters and 10 liters respectively, which is not high for the V6 engine with 3.5L displacement.

Universal 2.4L Ecotec engine

Technical features: all-aluminum body, D-VVT, double counter-rotating balance shaft, self-adjusting timing chain.

Application models: Buick New Regal and New LaCrosse.

GM’s 2.4L D-VVT Ecotec engine is a very familiar engine, which has been adopted in the domestic New Regal and New LaCrosse. The application of general-purpose Ecotec series engines in domestic models has changed the traditional impression that "American cars are used as waste oil". This engine originated from Opel, a European brand owned by GM, and has excellent performance in fuel economy and power.

1. All-aluminum engine material

The cylinder block and cylinder head are made of aluminum alloy and made by advanced technology, which greatly reduces the weight compared with the cast iron engine. At the same time, the all-aluminum engine is better than the cast iron engine in heat dissipation, which allows the engine to obtain higher speed.

2.D-VVT

The d word of D-VVT means double, double variable valve. That is, the dual valve timing of intake valve and exhaust valve can be adjusted. Through electronic timing, the opening and closing of intake valve and exhaust valve are accurately controlled. It achieves a large torque output in the low-speed region, and can have a peak torque of 90% in the low-speed region of 2400rpm, which greatly improves the responsiveness of the engine and greatly improves the power performance in daily driving environment while saving fuel.

3. Double counter-rotating balance shaft and timing chain

2.4L Ecotec engine adopts double counter-rotating balance shafts, that is, two balance shafts run at twice the speed of crankshaft to eliminate inertial vibration. It counteracts the reciprocating inertial vertical vibration generated when the linear four-cylinder engine is running, and improves the excellent noise reduction and shock absorption characteristics. Its drive system, like camshaft timing system and water pump drive system, is a maintenance-free chain drive, which is maintenance-free for life and completely abandons the troubles of timing adjustment and timing belt replacement.

Both the new Regal and the new LaCrosse in China are equipped with a general-purpose 2.4L Ecotec engine. This engine has a maximum power of 125kw and a maximum torque of 225Nm, which has a good performance in both the new Regal and the new LaCrosse, in which the new Regal accelerates 9.8 seconds per 100 kilometers and the new LaCrosse accelerates 10.4 seconds per 100 kilometers. Considering their body weights of 1.6 tons and 1.7 tons respectively, it is ideal to have such achievements. Moreover, the fuel consumption of the two cars is less than 10L, and the fuel economy has also been affirmed.

Modern 4.6L V8 Engine

Technical features: variable valve timing technology, variable intake system.

Application models: Hyundai Equus, American version of Lawns

Modern 4.6L V8 engine is the only V8 engine among the top ten engines in 2010. Today, with more and more emphasis on energy saving and emission reduction, it is really surprising that such a large-displacement engine can be selected into the top ten engines. According to the introduction of Ward’s Auto World, this engine focuses on improving the defects in noise, vibration and workmanship mentioned in the preceding paragraph, effectively reducing friction and winning high praise from the judges.

1. Full power and good fuel economy.

Modern 4.6L V8 engine adopts technologies such as variable valve timing and variable intake system. The engine has a displacement of 4.6L, double overhead camshafts, 32 valves, a maximum power of 385 HP (283kw), a maximum torque of 451 Nm, and a rising power of 84 HP/L.. Hyundai also added in-cylinder direct injection, variable valve lift and other technologies to further improve the engine’s power and economy. The standard fuel consumption of less than 10L per 100 kilometers makes this engine perform very well in economy.

2. Good quality and low price

Generally, models equipped with large-displacement V8 engines are very expensive, while in the United States, the price of modern lawns equipped with this engine is less than 40,000 dollars. Among many large-displacement models, the price of Hyundai Lawns is very attractive.

As for the selection of this modern V8 engine, Ward’s Auto World thinks that it is its greatest advantage to buy a model equipped with a V8 large displacement engine for less than $40,000. Although there is no obvious technical advantage, the V8 engine has inherent advantages in stability, output smoothness and power performance, so this engine can be selected. However, in today’s increasingly stress on environmental protection and emission reduction, it seems that putting a 4.6L V8 engine into the list of the top ten engines is somewhat contrary.

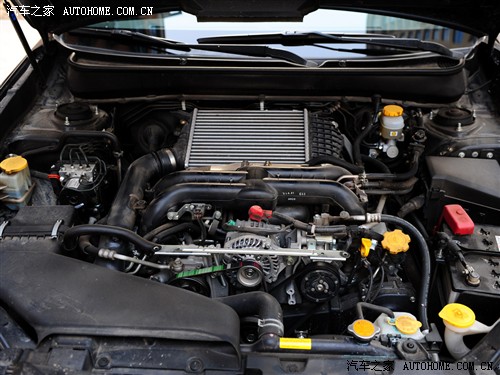

Subaru 2.5L horizontally opposed four-cylinder turbocharged engine

Technical features: horizontally opposed, turbocharged.

Application models: Subaru Legacy, Forester

Subaru’s horizontally opposed engine is very famous. The cylinder block and cylinder head of this 2.5T horizontally opposed four-cylinder engine are all made of aluminum, which has very good performance in heat dissipation and dynamic response speed. Subaru has further improved it to make it more stable.

1. The turbocharger position moves down.

The new turbine position is placed in the lower part of the engine, which reduces the center of gravity of the vehicle and is more conducive to vehicle handling; At the same time, it also shortens the distance from the three-way catalyst, thus making the working temperature of the three-way catalyst rise faster and further reducing the emission pollution.

2. horizontally opposed engine is more stable.

Horizontally opposed engine, the engine pistons are evenly distributed on both sides of the crankshaft and move left and right in the horizontal direction. The whole height of the engine is reduced, the length is shortened, the center of gravity of the whole vehicle is reduced, and the vehicle runs more stably. The engine is installed on the center line of the whole vehicle, and the moments generated by the pistons on both sides cancel each other, which greatly reduces the vibration of the vehicle during driving, so that the engine speed is greatly improved and the noise is reduced. At the same time, the lateral vibration generated by the engine is easily absorbed by the bracket, which effectively reduces the center of gravity of the heavier engine of the whole vehicle and makes it easier to achieve overall balance.

The self-Balu 2.5L horizontally opposed four-cylinder turbocharged engine is equipped with two cars in China, namely the Legacy 2.5GT and the Forester 2.5T.. This engine has a maximum power of 195kw and a maximum torque of 350Nm, which is very explosive. Moreover, compared with in-line and V-shaped engines, horizontally opposed engine has better performance in engine vibration.

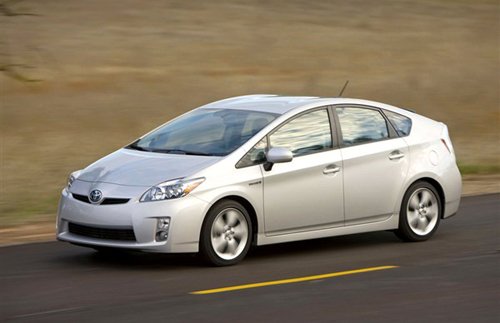

Toyota 1.8L Hybrid Hybrid Engine

Engine features: hybrid power

Application model: Toyota Prius (not introduced in China yet)

Toyota Prius was the first hybrid vehicle to enter the market. In the North American market, the new Prius replaced the previous 1.5L engine with a 1.8L engine, and the maximum power increased from 77 horsepower to 99 horsepower, while the power of the motor also increased to 80 horsepower. In addition, the new power system has no more improvement in hybrid technology.

1. 1.8L engine brings more power.

The third-generation Toyota Prius is equipped with Atkinson cycle 1.8L 4-cylinder engine, which replaces the old 1.5L engine. The maximum power is 98 horsepower, which is 22 horsepower higher than the old one, and the torque is 142Nm, which is 31Nm higher than the old one. In addition, the maximum power of the motor-powered vehicle is 134 horsepower, and the low-speed torque is further improved, which also means that better fuel economy can be obtained at low speed. The acceleration time of 0-100km/h is only 9.8 seconds.

2. Redesigned Hybrid Synergy Drive hybrid cooperative driving system.

The output power of the motor is further improved, and at the same time, the high voltage of the power supply system is realized, thus improving the efficiency of electric energy use. Toyota’s THS full hybrid power system has three driving modes, including the engine running alone to drive the vehicle, the battery acting alone to drive the vehicle and the two working together. The system can provide the optimal driving scheme under different driving conditions.

3. The power system is lighter

In the new hybrid power system, all components are lightweight. The converter, engine and power control unit are designed to be smaller, and the weight is correspondingly reduced by 20% compared with the previous generation.

The third-generation Prius will soon be introduced into China, which will further improve its power while maintaining the original fuel economy and environmental protection emissions. The new power system responds better at low speed and speeds up faster. The third-generation Prius is expected to be introduced into the China market this year, and this new hybrid system consisting of 1.8L engine and motor will also be carried by the new Prius made in China.

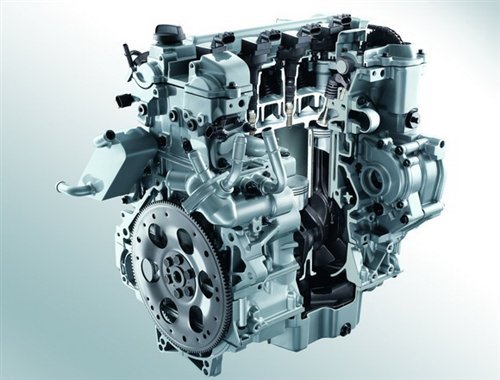

Volkswagen 2.0L TDI Turbocharged Diesel Engine

Technical features: high-pressure in-cylinder direct injection and adjustable vane turbocharging.

Application models: American Jetta and Golf (not introduced in China)

This is the second diesel engine among the top ten engines. Volkswagen TDI engine is a practical engine. With the combination of high-pressure fuel injection technology and adjustable vane turbocharger and other new technologies, Volkswagen 2.0TDI diesel engine has outstanding performance in economy and power.

1. High pressure fuel injector

The fuel injection pressure of TDI is as high as 1920bar, which is developed for the fact that the combustion quality directly depends on the absolute pressure when the fuel is injected into the cylinder. TDI engine has one pump nozzle per cylinder, and the amount of diesel oil required for power stroke of each cylinder is divided into two parts: pre-injection and main injection. The main injection is carried out after the crankshaft rotates several degrees after the pre-injection, and the interval between them is controlled by a hydraulic mechanism. The injection time, injection quantity and injection stop time are all controlled by solenoid valves. The high-pressure injection technology makes the diesel engine achieve the ideal state of stable and efficient combustion, and reduces the combustion noise and the content of nitrogen oxides in the tail gas.

2. Adjustable vane turbocharger

The traditional turbocharger has the disadvantages of charging lag and power neutral at low engine speed, while the adjustable vane turbocharger used in TDI engine can generate the required intake pressure at any engine speed, and its performance is greatly improved compared with the traditional turbocharger, which improves the adaptability of the engine and can ensure high power output at low engine speed. Because the intake pressure of the engine is always in the best state, the combustion efficiency is improved, the fuel is saved and the emission is improved in the whole speed range.

Volkswagen 2.0TDI diesel engine adopts cast iron cylinder block and all-aluminum cylinder head, which is much stronger than all-aluminum cylinder block in strength. This engine has a maximum power of 104kw/4000rpm and a maximum torque of 320Nm/1750-2500rpm, and has a very strong low-speed torque performance. However, due to various reasons in China, Volkswagen’s TDI engine has not been popularized in China.

◆ For related reading, please click:

1. Introduction of three common power steering systems with different strengths.

//www.autohome.com.cn/drive/201006/122419.html

2. Starting from the basics, Audi’s driving safety training.

//www.autohome.com.cn/drive/201005/116584.html